FERGO Rect

Rectangular ventilation duct

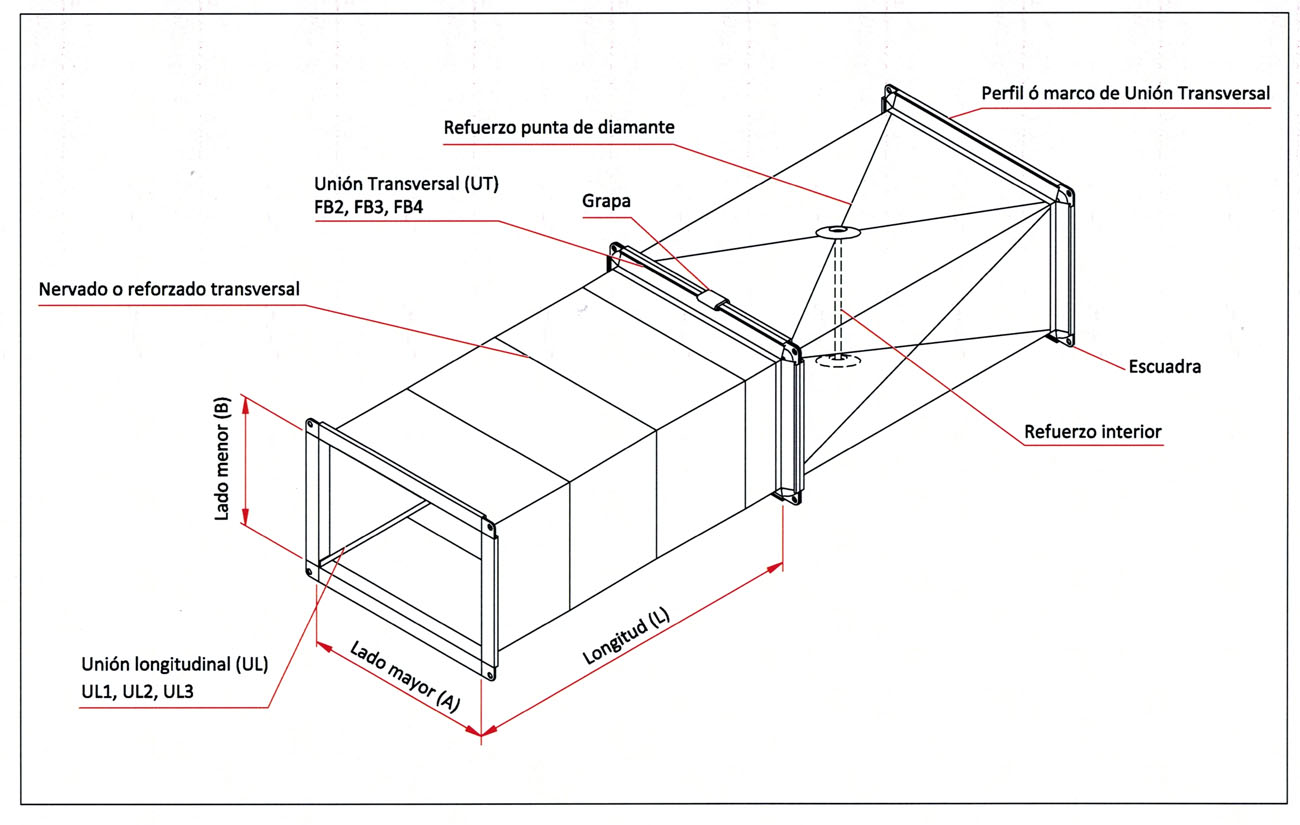

In the illustration below the most important points and construction details involved in the manufacture of a rectangular ventilation duct observed FERGO Rect. In this scheme all possible constructive options are collected. In practice, You will be chosen by a type of UL, UT model, the kind of enervated, reinforcements if needed , depending on the dimensions (A,B and L) the rectangular duct and service pressures.

FB binding frameworks for rectangular ventilation duct FERGO Rect

In use the preformed frame Fergotub dimension FB 20, 30 and 40 and fixing the four corners by screws.

The main advantages are:

- Economy

- Ease of Installation (also in situ)

- Robustness

- Several profile types with improved sealing

The joint between the pipes is sealed with adhesive using a polyethylene gasket 4×9.

The following table shows the maximum dimension of the longest side indicated “A” a rectangular ventilation duct, FERGO Rect, depending on the operating pressure and the FB profile used in the transverse juncture UT, to achieve the best performance of stiffness and tightness.

| PROFILE TYPE | Maximum width duct(mm) The 500Pa | Maximum width duct(mm) The 1000Pa | Maximum width duct(mm) The 2500Pa |

|---|---|---|---|

| FB2 | 1000 | 800 | 600 |

| FB3 | 1300 | 1100 | 900 |

| FB4 | 2500 | 2000 | 1400 |

Reinforcements and intermediate junctions rectangular ventilation duct FERGO Rect

Consider that each transverse joint is made by fixing the corners with four screws. If the width of the duct is considerable, there is a tendency to separate frames in the middle. To correct this defect intermediate joints or clamps are used.

Basically are of the types, the screw and the slide. They are like an inverted U that are housed in the nose of each frame, approaching the two sections to each other.

Also, when operating pressures are medium or high and dimensions of the rectangular duct considerable ,frames may flecten . International standards support a maximum deflection of 4 thousandth of the width of the duct. For a given plate thickness and binding framework , is possible to increase the width of the duct using Cleats. Basically these reinforcements consist of a tube of 3/8 "to atiranta opposite sides of the conduit. They act in two ways: placed 50mm from the mouth to prevent the deformation of the joint , while placed in intermediate positions prevent deformation of the faces of the duct.