Passive fire protection

Passive fire protection is a series of construction elements and materials with suitable properties to prevent the onset of fire (flame retardants), prevent the spread (compartmentalization, enclosures, ducts etc.…), prevent structural degradation (protection of the structure) , facilitating the evacuation of occupants and the performance of the mass extinction. Thus, products of passive fire protection must meet current regulations based on strict laboratory tests that make them suitable for this purpose.

Ultimately, fire regulations define stability and curb the spread of fire-bearing structures, and confinement warranties or segmentation of a fire to facilitate evacuation.

Regulations. Basic Document SI Safety in case of fire

This section of CTE basic requirements are reflected in “Safety in case of fire SI” to be met by buildings and facilities, to reduce to acceptable limits the risk that the users of a building suffer damage resulting from accidental cause fire, due to the characteristics of your project, building, Use and maintenance.

These are measures that affect the following sections: Fire spread inside, spread by the outer, evacuation of occupants, fire protection facilities and ease to the intervention of firefighters.

The scope is limited to public and private buildings of new construction and rehabilitation of existing buildings, except for an industrial buildings that are governed by the “Fire Safety Regulations in industrial establishments”.

AND 1- 3.3 Interior.Espacios hidden Propagation. Step facilities through fire partitioning elements

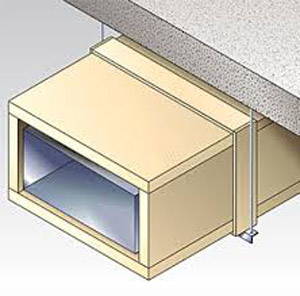

The fire resistance to fire partitioning elements must be maintained in the points where these elements are traversed by elements facilities , such as cables,pipes, lines , ducts ventilation, etc., excluding penetrations whose passage section does not exceed 50cm2. This can opt for one of the following alternatives:

- a) Providing an element, in case of fire, automatically clogging the passage section and ensured that point the fire resistance at least equal to the crossing member, for example, an automatic fire damper EI t (i<->the) where t is the time required fire resistance element partitioning crossed, or a device intumescent seal.

- b) Penetrations to provide an at least equal resistance element traversed,for example, ducts ventilation NOT t(i<->the).

AND 3-8 Evacuation of occupants. Control of fire smoke

Use Zone Parking, Commercial establishments or use public Concurrency whose occupation exceeds 1000 people and Atrios or dispose of excess over 500 people, there will be a smoke control system capable of ensuring fire such control during evacuation.

For it must be ensured Parking:

- a) The system can extract 150 l / s square and a flow injection 120 l/s plaza.

- b) Fans shall be rated F 300 60.

- c) The ducts crossing through a single sector of fire must be rated E 300 60. The ducts crossing separating elements of fire sectors must be rated at least ITS 60

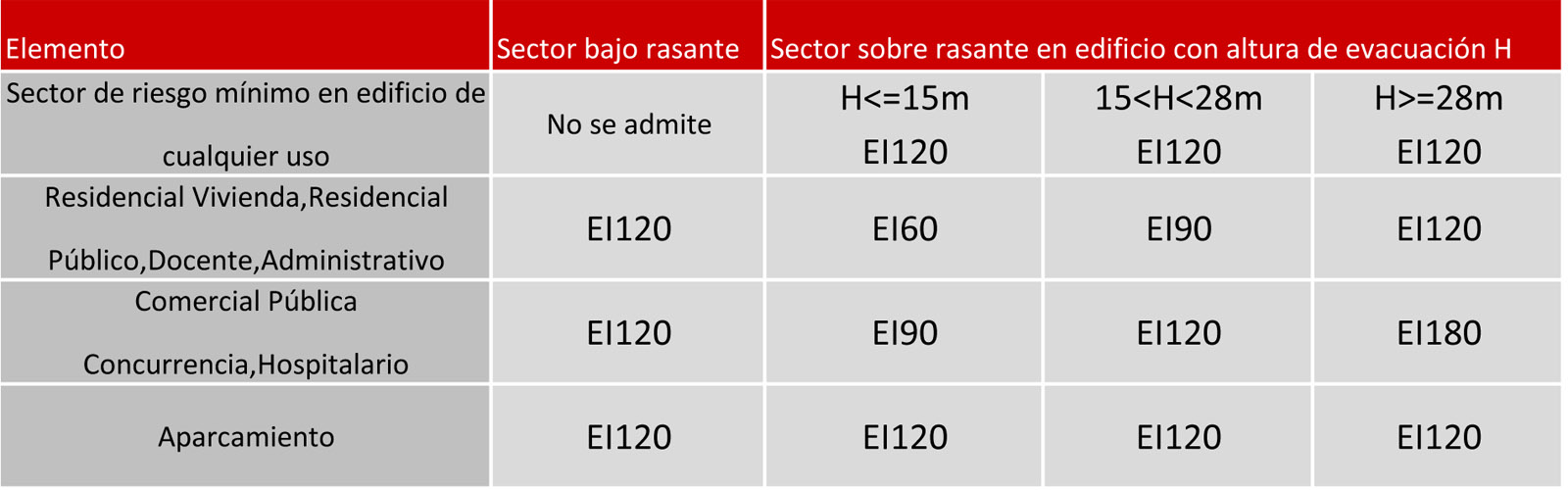

Fire resistance of walls and ceilings bounding fire sectors

How is called a conduit EI ?

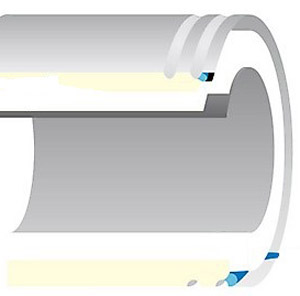

The concept of EI fire resistance of a ventilation duct comprises three fundamental aspects:

- Dimensional stability, rigidity and strength

- Containment of flames and smoke caused by fire. Effect smoke fire barrier to the unexposed face, preventing ignition material adjacent to that surface.

- Degree of isolation. Guarantee that the temperature of the unexposed side does not exceed 180 ° C.

The correct name is the type E t ho-ve (i-th), meaning each character

t the minimum shelf life of these properties

I duct with horizontal alignment and vertical alignment conduit

i fire inside the duct the fire outside the duct

A conduit for each situation EI

Several systems make a ventilation duct meets the exacting standards of safety-fire. We can classify two trends :

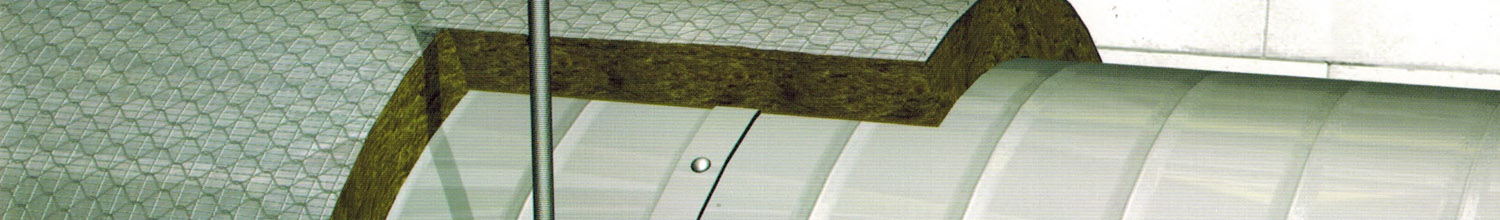

- Using materials with EI certification. Metal constructions are jacketed with a ceramic insulation or rock wool high density, usually made of stainless steel.

- Use of coating materials to provide the base of the duct proper certification EI. At this level are two solutions:

- The silicate boards very high density, of 450 a 900 Kg / m3 used as lining conventional ventilation ducts.

- Rockwool high density, around 120 Kg/m3. Finished with aluminum foil for rectangular ducts and extra metal mesh circular ducts. Thickness 30 a 115mm

Advantage: Standard ductwork easy assembly. Suitable for mounting outdoors.

Drawbacks: Expensive system because of the nature of the materials used. Requires good study paths for implementation. No certification at all typologies of fire.

Advantage: Enables existing ducts.

Drawbacks: The assembly is treated more as of the woodwork . Extremely heavy structures that increase spending on soportación. It tolerates mounts to the outside. Price moderate to high.

Advantage: Enables existing ducts. Moderate weight (a 65% Unless other systems). Easy assembly. Half price. It is contemplated certificate for all typologies of fire.

Drawbacks: It tolerates mounts to the outside.