Properties rectangular ventilation ducts

Ducts modern networks consist of several types of elements in composition of materials (plate, fiber, textiles ...) and geometric typology (rectangular,circular, Oval ...). But perhaps the metallic ventilation ducts most widespread and well known are the rectangular ventilation ducts.

In recent years the rectangular ventilation ducts has undergone profound changes in manufacturing systems, from an artisan to design an automated execution, substantially improving bonding systems and timing of development, ie improving tightness and economy of installation and assembly.

In response to the pressure of , air velocity and sealing ductwork, manufacturers offer different solutions for implementing the ducts rectangular ventilation , passing through work with several thicknesses of galvanized and different systems of longitudinal and transverse joint union.

Follow UNE 100-102-88 sheet metal ducts are classified according to the maximum air pressure in exercise and maximum fan speed according the table on the right.

UNE 100-104-88 provided that to ensure tightness duct, both circular and rectangular ducts, seaming needed as indicated below:

- Clases B.1,B.2 y B.3: Seal transverse joints

- Clases M.1 y M.2: Seal the transverse and longitudinal joints.

- Clases M.3 y A.1: Seal all connecting elements transverse and longitudinal, connections, corners, screws and rivets etc ...

The key points in the construction of rectangular ventilation ducts and give it its properties are the longitudinal and transverse joints, combined with the sheet thickness and the type of reinforcement for major sections.

| Class duct | Maximum pressure in exercise (Pa) | Maximum Speed (m/s) |

|---|---|---|

| B.1 (come down) | 150(1) | 10 |

| B.2 (come down) | 250(1) | 12,5 |

| B.3 (come down) | 500(1) | 12,5 |

| M.1 (media) | 750(1) | 20 |

| M.2 (media) | 1000(2) | (3) |

| M.3 (media) | 1500(2) | (3) |

| A.1 (high) | 2500(2) | (3) |

| (1) Positive pressure to negative | (2) Positive pressure | (3) Speed usually greater than 10m / s |

Union longitudinal rectangular ventilation ducts

There are many, but we will highlight the most important by common usage among manufacturers.

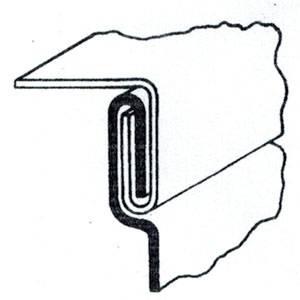

– Close type PITTSBURGH (UL1)

– Close type ACME (UL2)

– Close type CLIP (UL3)

Ducts for pressure classes M1, M2, M3 and A1 only be used longitudinal seams and UL1 UL2.

Ducts with close UL3 are very practical for use as the outer shell of rectangular metal duct isolated. Also supplied dismantled to minimize transport costs to work. His bonding system works is simple and fast.

Union transverse rectangular duct

Classically the transverse joints of rectangular ducts have been varied, but the demands on rigidity and sealing performance required of air handling systems has limited the use to a small range.

- – Marco preformed pyramidal geometry for welding or riveting of mouth duct.

- – Preformed duct integrated framework

- – Marco angle drilling for special designs.

Anyway, used independently of the binding between the binding is effected ducts facing flat surfaces of the metallic frames together, and setting or by the four corners (type 1 and 2) or screws along the perimeter (type 3). To have a good level of sealing, is necessary to use boards that stand between the flat sides of the frames. We must pay special attention to the critical points that represent the corners.

To increase the stiffness of the pipes is very common marking the flat surfaces, and further large, with small folds that confer greater stability to the finish line. Are known by marking "diamond point" marking the two diagonals, or the slightly enervated marking faces transversely of conduit.

In use the preformed frame Fergotub dimension FB 20, 30 and 40. The use of one type or another depends on the size of the large face and the pressure of. A correct choice will allow us to achieve the best performance of the ductwork in structural stiffness and tightness. Our recommendation