DUCT ASSEMBLY QUICK GUIDE PARKING

This document is intended as a quick guide providing the proper guidelines and procedures for assembly

parking conduit to ensure the installation to the current regulations.

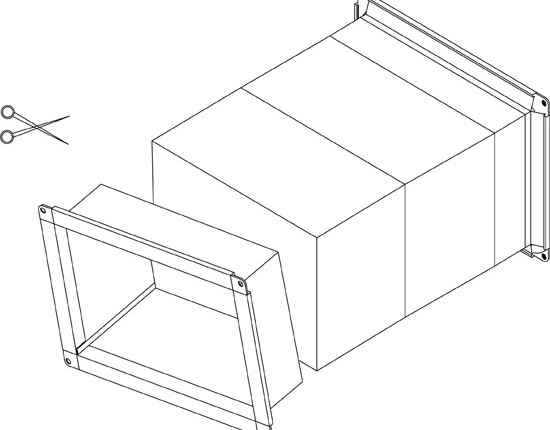

MOUNTING SEQUENCE OF 2 SECTIONS BETWEEN YES

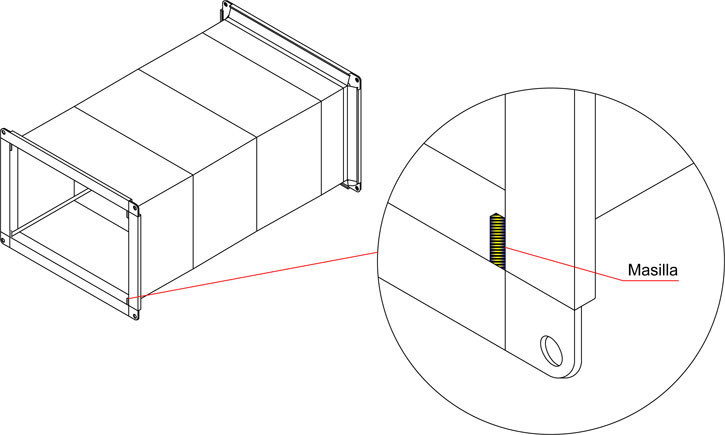

Inspect the pipe factory received

Check for possible dents and deformations that may have been

produced during transportation

Discard parts with significant damage